Customer orders

Customer orders

All planned goods outbound shipments are controlled via customer orders. Customer orders can be created in a variety of ways:

Manual creation via the overview in customer orders by clicking on the "Add customer order" button.

Creation via the shopfloor by filling a shopping cart.

Transfer of an order via an interface, for example via the message type "CustomerOrders_vX".

Each customer order consists of a customer order header and the customer order items. Attachments and images can also be stored.

Customer order header

A wide variety of information can be stored in the order header. All fields can also be transferred and reported back via an interface, e.g. via message types. Mandatory fields include a unique order number, the client and the recipient (depending on the warehouse options, the client may also be a mandatory field).

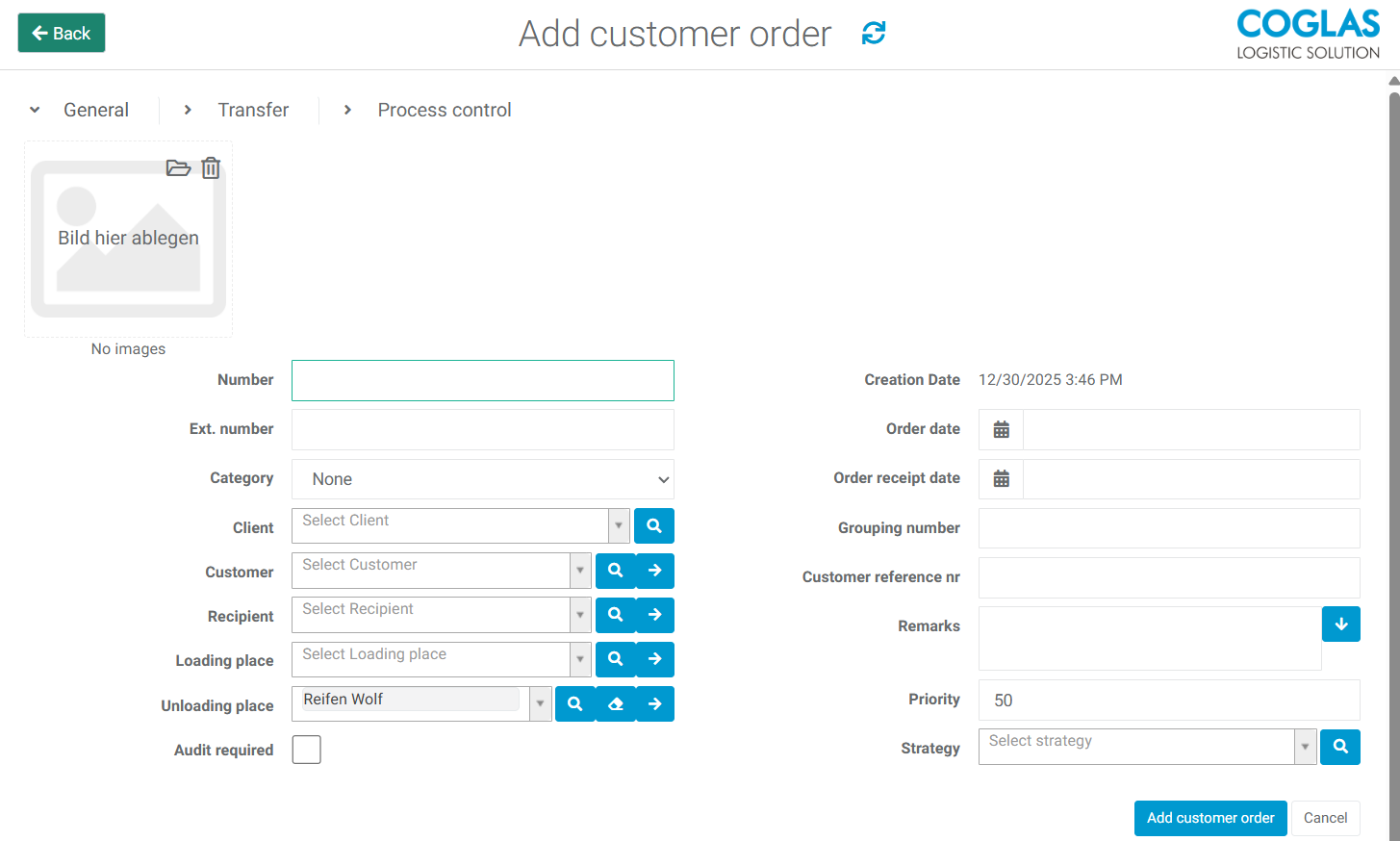

General

In the "General" tab of the customer order header, in addition to the mandatory fields, general information such as the loading place, unloading place, remarks and various data such as the order date or order receipt date can be maintained. External numbers or customer reference numbers can also be stored. If nothing is stored in the strategy, the default strategy for the item or client is used first. If these are not maintained, the general default strategy for customer orders is automatically selected for inventory assignment. In addition, the order can be deactivated here if it is in the correct status or, alternatively, set to "Audit required".

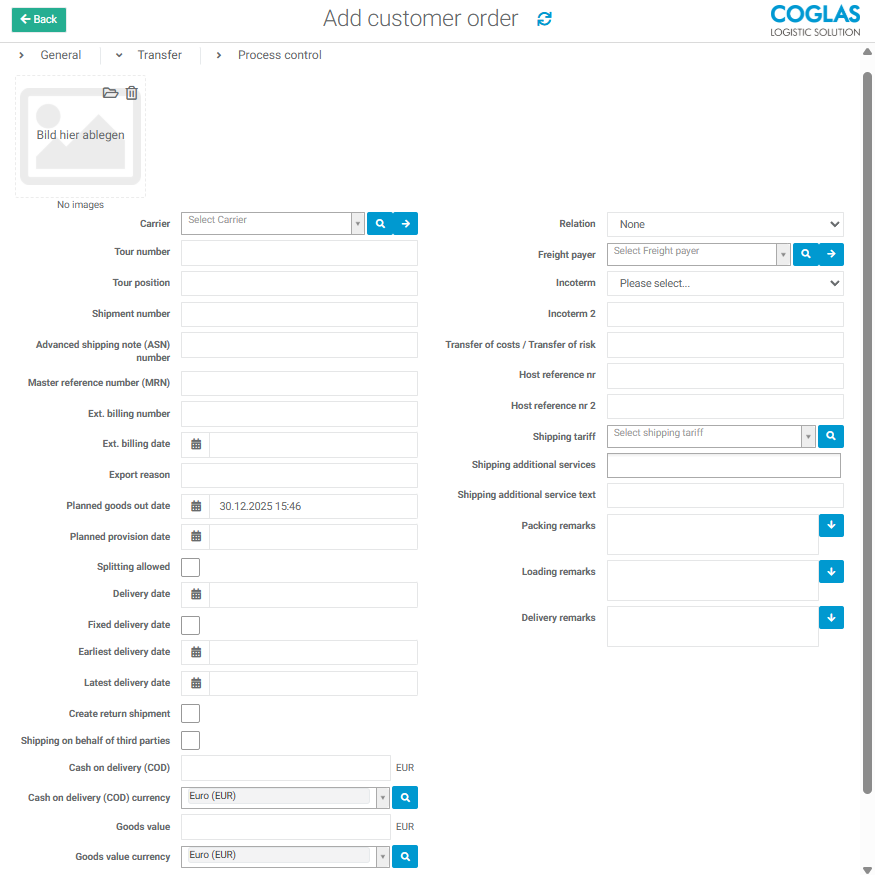

Transfer

All information that could be relevant to transport can be stored in the Transfer tab. This includes the carrier and the associated shipping rate, but also delivery terms (Incoterms), freight payer, delivery date, etc. Notes (for packaging, loading and delivery) can also be added to the order. Customs-related information such as the MRN, external invoice number and invoice date, reason for export and goods values can also be specified.

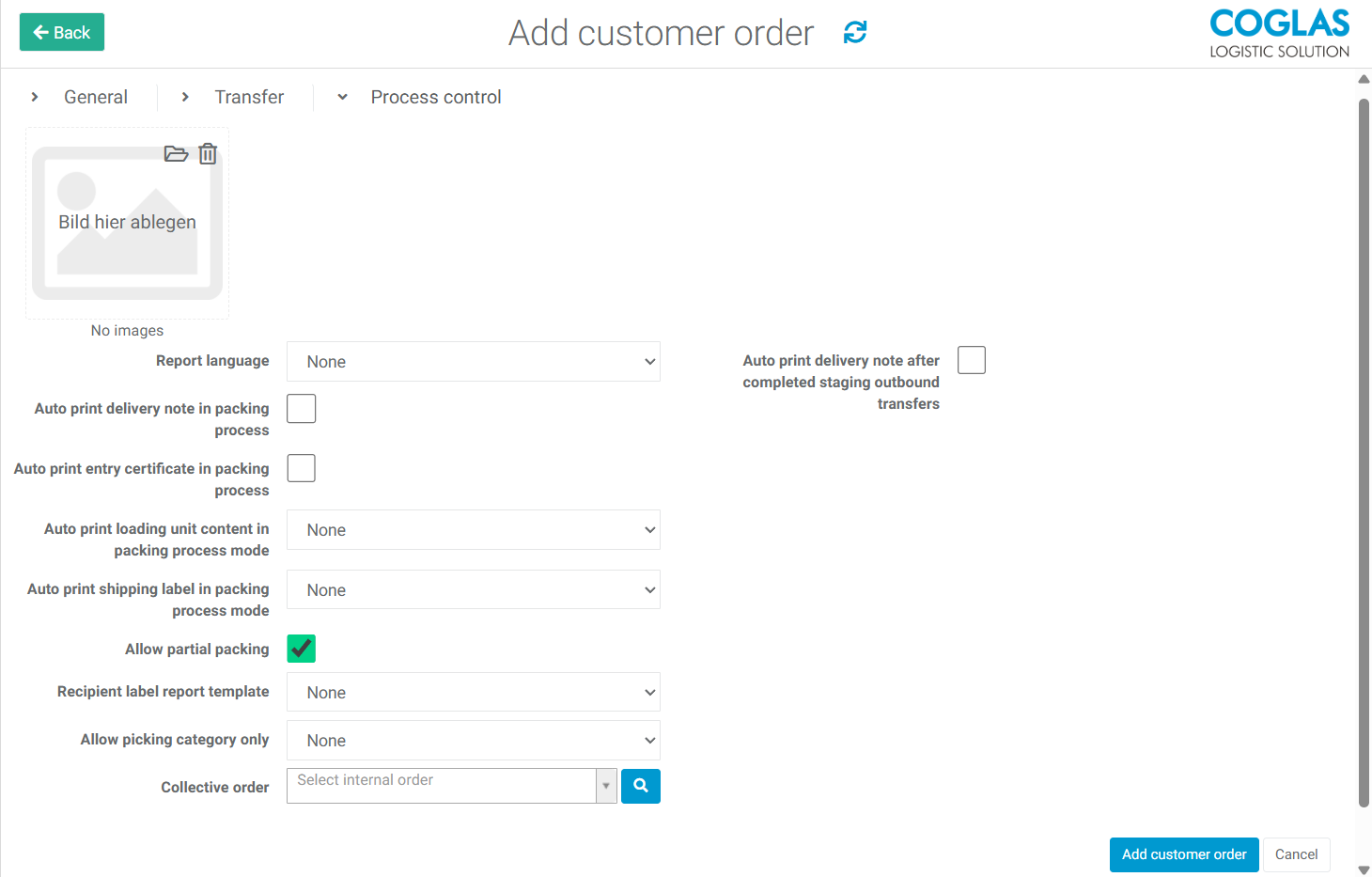

Process control

Process-related settings can be made for the order in the process control section. For example, automatic report printing can be stored, or it can be determined whether an order may be partially packed.

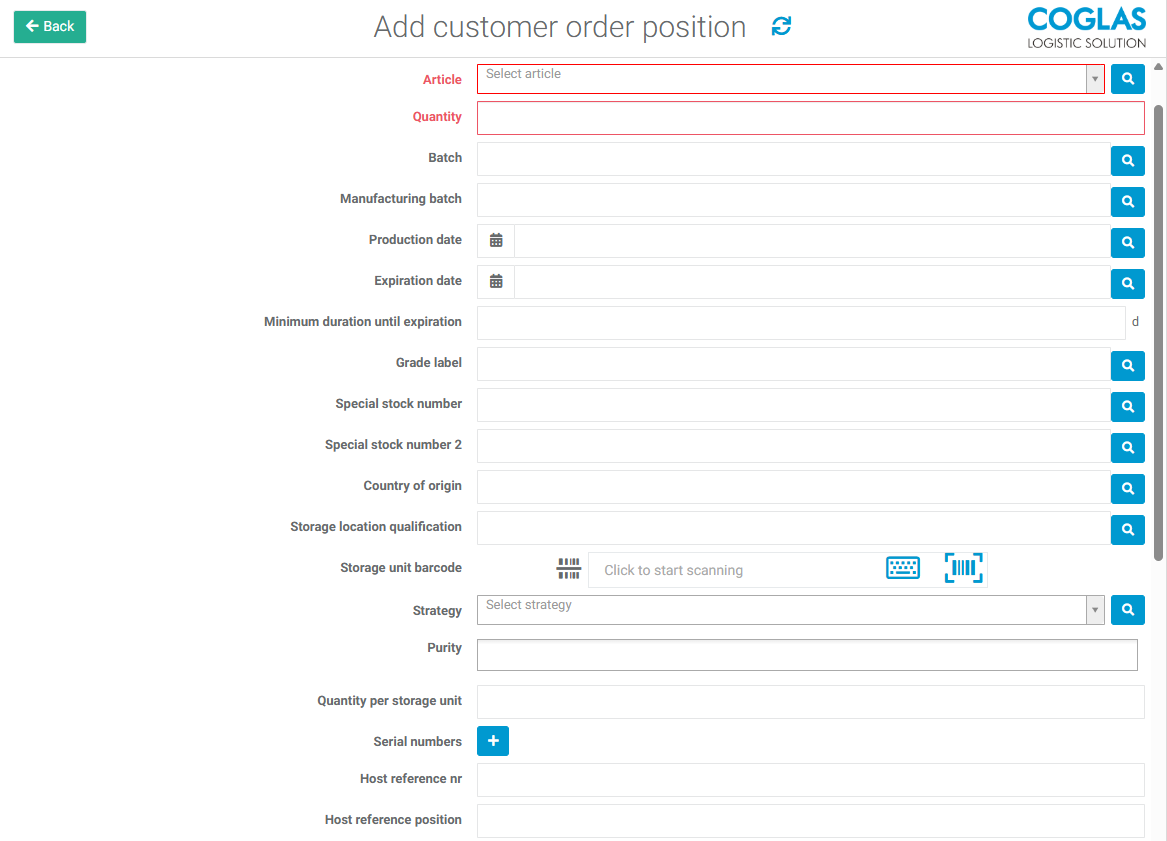

Customer order position

When the customer order is created via the shopfloor, the order items are transferred directly from the shopping cart. They can also be transferred directly via the interface or entered manually.

For manual creation, press the “Add new position” button below the order header to open the input mask. The item and quantity are mandatory fields when adding an order position. In addition to additional information such as the reference number, shipment number, goods value or comments, inventory qualifications can also be specified. These include, for example, the batch, the country of origin, but also the best-before date or a special stock number and others. These can either be entered or, by clicking on the lens, the corresponding inventory qualifications for the item are displayed and can be selected.

Start order

As soon as a customer order including at least one item has been entered, the ‘Start order’ button can be used to automatically assign stock reservations based on the selected strategy and create corresponding transport & picking orders.

Depending on the configuration, one of the following scenarios is set as the default for the Start order function. Alternatively, the other option can be called up for each order using the small arrow next to the ‘Start order’ button.

Start order for staging:

Both picking orders and transport orders for full pallets are generated, all of which have staging as their destination. The goods can therefore be consolidated from the different storage areas and prepared for dispatch if there is enough free space.

Start order for picking:

Only picking orders are generated. Transport orders for full pallets are only generated when loading starts and point directly from the current storage location of the SU to the goods issue gate or the loading area. This skips the interim storage in the staging area - particularly helpful in the event of capacity bottlenecks in the loading area.

Volume planning

The volume calculation for the requirement of picking and packing storage units is only triggered when the order is started. The aim is always to have as few storage units in total as possible and at the same time to use the most suitable container sizes.

Only load carriers that are labelled ‘Suitable for order picking’ are used for order picking planning. Only the requirements of a customer order that are to be provided via order picking are taken into account. Full pallets are therefore not taken into account!

The calculated unit load requirement is also used as the basis for setting up the pick trolley. Further information on the multi-pick can be found in the chapter Transport → Picking.

Only loading aids that are labelled ‘Suitable for packaging’ are used for packaging planning. All items and quantities of the customer order are taken into account when calculating the total volume.

Methodology of the calculation:

The space requirement of an item is normalised: the largest dimension (length, width or height) is checked against the storage unit.

Items that do not fit into the largest container or whose master data is not complete are collected in a SU of the largest type.

Items with a nesting factor are also taken into account when calculating the volume.

Packaging planning can be deactivated for individual carriers under Business Partners in the Process Control tab. To do this, select the “Disable auto packing planning” checkbox. This means that packaging planning will no longer be run when the order is started.

Customer order position

In the detailed view of the item, specifications for stock determination can be made for the respective item. Entered values, e.g. batch, must be congruent between the specification and the desired stock. If there is no stock with the entered batch in the warehouse, the order cannot be started - no suitable goods are available.

Manual stock allocation:

In addition to automatic replenishment, it is also possible to allocate specific stocks to an order on a dedicated basis.

Whole storage unit: A specific, whole container should be reserved for the required item. Processing takes place via transport

Picking: The required item is to be picked from a specific source SU. Processing takes place via picking.

Accept shortages:

In the event of missing parts (not enough stock available) or at manual request, items can be finalised and thus under-delivered. This is possible for the total quantity as well as for partial quantities of the item.

Manually closed positions cannot be reopened once the security enquiry has been confirmed!

Customer order status

Status | Bedeutung |

|---|---|

Created | The order has been created or transferred and has not yet been started. |

Shortage quantity | The order has been initiated, but the stock could not be fully covered. |

Audit required | “Inspection required” has been activated via interface or manually. This overrides any other status. |

Inventory assignment | At least one item has the status "inventory assignment allocation", meaning that the order item has been fully reserved, but no transports or picking have been started yet. Either only the reservation for the sales order has been started, or there are still hauling demands open for the order. |

Order picking | All items are in picking status, so there are picking orders for this order. |

in process | At least one item has the status “in process”. Even if individual items still have the status “picking”, the header status is “in process” if one item is “in process”. Transport orders then exist for this item. |

Ready for loading | All items are provided in the "staging outbound" area. |

ready for shipment | The goods have been prepared for dispatch. |

Partially packed | Some of the goods were packaged during the packing process. |

Completely packed | All goods were packaged during the packing process. |

partially dispatched | Part of the goods was booked out via the goods out process. |

Done | All goods were booked out via the goods out process. |

Reported to ERP | If a service configuration with "DeliveryOrderOut" is set up, the status is transferred to the external system. This then sets the status to "Reported to ERP". |

Deactivated | The order has been set to deactivated manually or via interface. It can no longer be deployed. |

Explanation of "shortage quantity" status:

If, after the order has been started, an order item can only be partially covered or not covered at all and the complete quantity cannot be allocated, the item status changes to "shortage quantity" status. If an item has shortage status, the order header also changes to shortage status.

Billing

Provided Services

Additional activities can be entered that are to be taken into account in the course of billing. The desired services must first be entered in the billing configuration before they can be used in the customer order. Further information can be found in the chapter Billing → Warehouse services.

Billing

Opens the invoice for the current sales order and displays all relevant items. Further information can be found in the Billing chapter.

→ back to COGLAS processes

→ back to COGLAS menu