Goods out receipts

General

The overview shows the list of all outgoing goods with their status. In addition to the tour number and the forwarding agent, it also contains the order numbers and the number of storage units belonging to the tour.

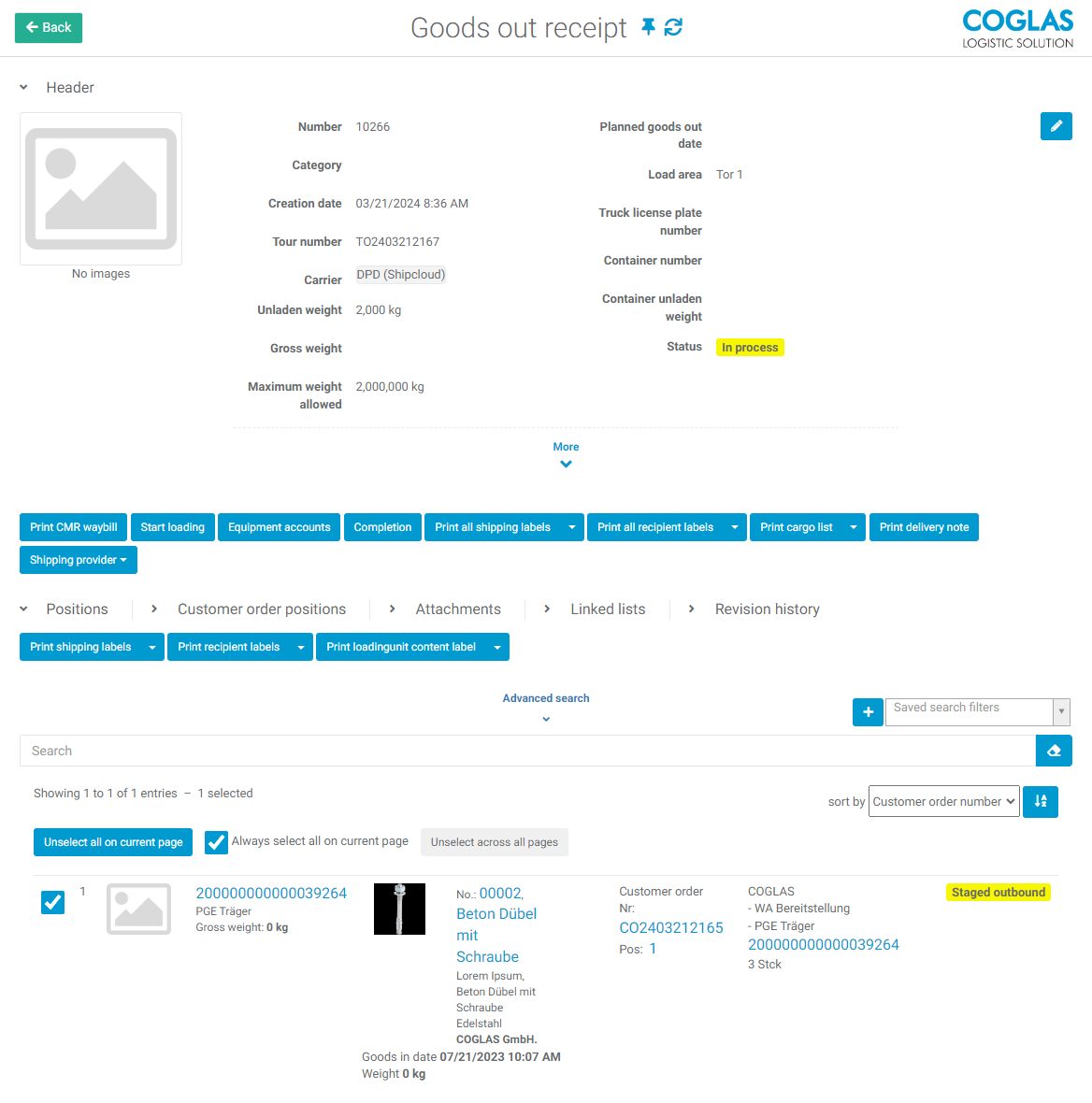

Selecting a goods issue opens the detailed view. This is where the printing of the goods issue documents and the posting of the goods after collection are initiated.

Stock removals are carried out on the basis of customer orders. An order is a request to remove goods from storage and make them available for goods issue. This specifies which items are to be brought to which delivery destination, in which quantities and with which stock attributes.

In principle, orders can be created in two ways:

The host transfers the order to the system via an interface.

The user creates the order manually.

An order consists of:

an order header

1 to n order items

Images and any files can be attached.

Outsourcing comprises the following steps:

Create order for stock removal

Start order

Generate stock reservations for this order (manual/automatic)

Carry out picking and/or provision of full pallets

De-/consolidation of stocks via packaging (optional)

Carry out loading

Post goods issue

Buttons

Button | Description |

|---|---|

Print loading list | Creation of the loading list as an accompanying document for the carrier. |

Print delivery note | Generation of delivery bills, grouped by the receiver(s) of the shipments. |

Print CMR waybill | Generation of a standardized CMR waybill. |

Print shipping labels | Generation of shipping labels for all selected loading units. |

Book out | Completes the tour and changes the status of all customer orders to “Completed”. The stocks are booked out of the warehouse. If the interface is active, the required data will be sent to the host. |

→ back to COGLAS processes

→ back to COGLAS menu