Hauling

General

Pre-collection describes the provision of storage units that need to be accessed shortly. The stock is made available in the picking area. In principle, material is moved to the access zone. As soon as the stock is available in the picking area, the associated customer orders are started automatically.

Prerequisites

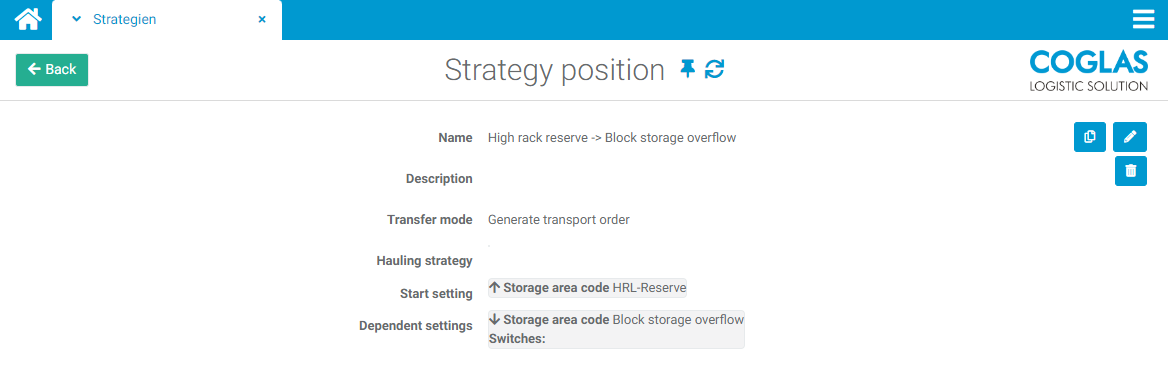

Pre-pick strategy configured, e.g. from a reserve area (HBW) to a block storage area:

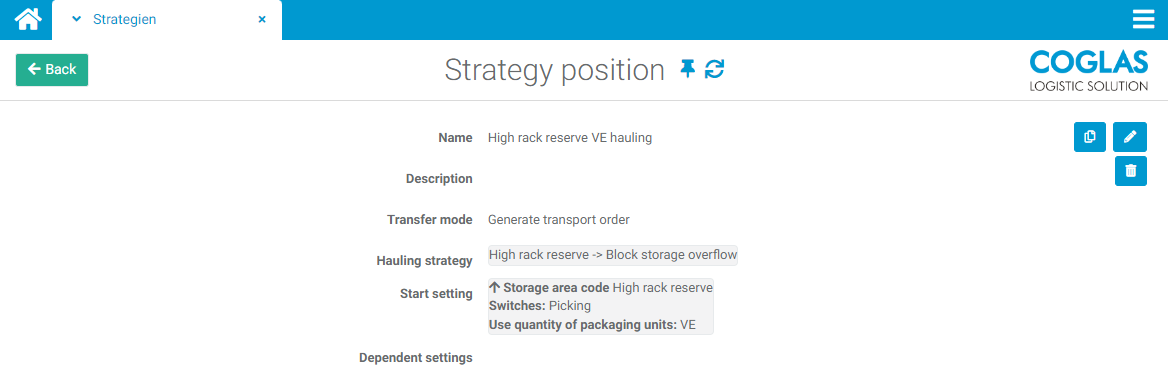

Strategy (e.g. customer order, production or internal):

The strategy (e.g. type: sales order, production, internal) is reserved in the source area of the pre-picking strategy by picking and the pre-picking strategy also points from the source area and transfers to the target area. The associated lists are then started automatically.

Process description

Start lists (e.g. sales orders) with strategy

Stock allocations are made in the source area (e.g. HRL reserve)

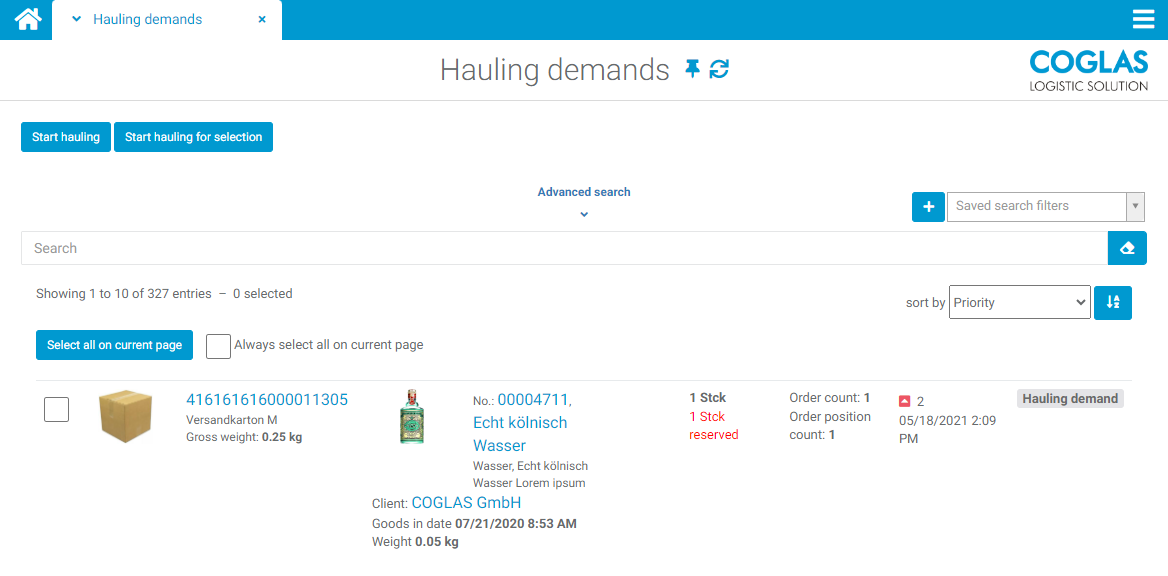

Pre-catch requirements are displayed in the "Pre-catch requirements" form.

All pre-collection transports are displayed under the "Pre-collection" transport category.

User executes pre-collection transport.

As soon as the destination scan of the pre-collection transport takes place, the sales orders are automatically started.

General notes

The following list types are relevant for pre-collection:

Production, sales order and internal order

Stock allocations in HRL / DLK / FB:

Always specific stock allocations (red)

Stock allocations in block storage:

Always optional stock allocations (yellow)

During a transfer from bulk storage to a HBW picking area, the stock allocation changes from an optional to a concrete stock allocation and vice versa (HBW reserve in bulk storage from concrete to optional reservation)

Stock allocations are converted from optional to specific:

Optional stock allocations are converted to concrete according to priority and, depending on the order type, planned order date, production data, creation date.

Consideration of articles and stock qualifications (e.g. batch, SBK,...)

Optional stock allocations are assigned to the SSCC concrete according to priority until the free stock is fully utilised

Hauling demands requirements:

The lead time requirements are listed under COGLAS → System → Lead time requirements. All areas (storage area codes) that have been created in a source settings in a "Lead time" strategy type are displayed in this form.

Buttons:

Start pre-collection: transports are created from the source area to the target area for all storage units with the status "Pre-collection requirement". The transports are displayed under Transport → Pre-collection and can be edited by the user.

Start pre-collection for selected storage units: transports are only created from the source area to the target area for the selected storage units.

→ back to COGLAS processes

→ back to COGLAS menu