Multi order picking

General

Multi-pick (cross-order picking).

With multi-pick, the picker processes several customer orders simultaneously, which are combined into one batch. At the first stage, picking is order-neutral and material-orientated. The 1-n customer orders are set up either automatically or manually on the transport trolley (multi-pick trolley). The KLE (picking storage unit) is then married to the multi-pick trolley. The customer orders are either picked together in one container or in separate containers (KLE - picking storage unit). This principle reduces the walking distances (dead times) of the order pickers. As a result, more customer orders can be processed in less time and efficiency is increased.

Topology overview

Warehouse overview

(..) - Transport trolley - WA01

(..) - Transport trolley - WA02 etc.

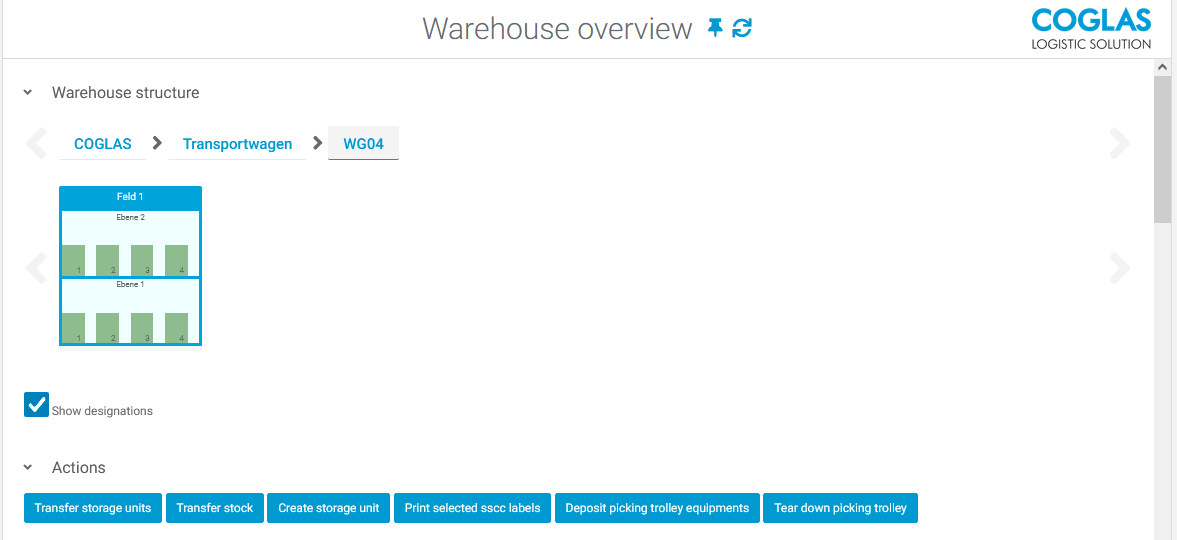

See Image 1 for an example of the Warehouse overview for the transport trolley.

The transport trolley WA04 has one Field with 2 levels and 4 storage locations each for a picking container assignment.

A total of 8 picking containers can be set up on the WA04 transport trolley.

Depending on the number of picking containers for a customer order, 1-8 customer orders can be set up here and started for the Multipick tour.

The warehouse overview has additional buttons for the transport trolley:

See Image Buttons bar at the bottom right.

[Deposit picking trolley equipments] button

At the end of picking, unused picking containers must be disarmed.

If the [Deposit picking trolley equipments] button is clicked, all empty picking containers are disarmed in the staging area.

[Tear down picking trolley] button

The transport trolley for a multipick setup has been started.

The transport trolley is now selected and no longer available for selection by other sessions and other users.

To cancel the multipick setup use the button [Tear down picking trolley].

Note! The [Tear down picking trolley] button only works with an empty transport trolley.

Default process : End of picking

Picking has been completed and all picking containers have been used and disarmed. The transport trolley is now automatically reset and is available for a new multipick tour.

Both buttons are therefore not required for a normal picking process!

Multipick

Prerequisite for picking different customer orders into a picking container during manual set-up:

Same Client

same Carrier

same Recipient

(exception: pick trolley set-up with active ‘Mixed order picking’ checkbox allows different recipients).

Additionally: A warehouse structure for a transport trolley must exists. A high rack with the option “Movable=true“.

Function | Description | |

|---|---|---|

| 1 | Process history | Customer order menu

Picking menu

|

| 2 | Mixer assignment on a picking container | Several customer orders are to be stored together in one picking container. Requirement for picking different customer orders into a picking contianer during manual set-up:

Exception: Pick trolley set-up with active ‘Mixed order picking’ checkbox allows different recipients. |

| 3 | Disarm picking container(s) | ‘Automatic disassembly’ function

‘Manual teardown’ function

|

| 4 | End of multi-pick order picking | At the end of picking for the multi-pick, the customer order is set to the status ‘Ready for loading’. Subsequent processes can be started. |

FAQ

Situation | Cause | Solution | |

|---|---|---|---|

| 1 | Mixed order picking MultiPick Mixed picking does not work for manual set-up. It is not possible to pick 2 orders in one box. | See ‘Mixer assignment on a picking container’ | The requirements must be met for KLE storage. |

| 2 | Customer order was set up on a transport trolley. How can the setup for an order be taken back? | There is no option to take back or cancel the customer order on a transport trolley. | Alternative:

|

→ back to COGLAS processes

→ back to COGLAS menu