Serial numbers

General

The management of serial numbers in the COGLAS Web WMS enables the seamless traceability of products with unique serial numbers from delivery to dispatch. This function not only supports the storage of individual serial numbers, but also their precise recording for incoming and outgoing goods in order to precisely document the origin and use of items. The serial number can only be recorded once in the system (in the life cycle from goods receipt to goods issue).

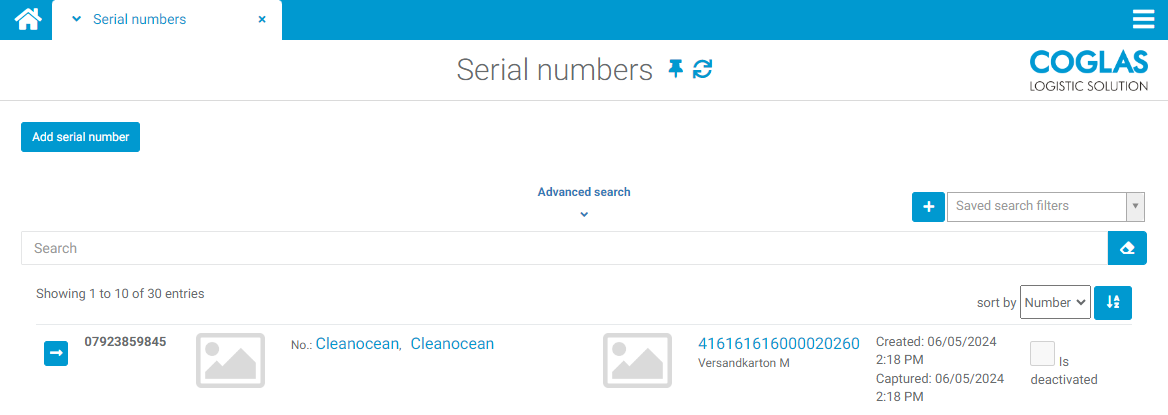

Serial numbers overview

Serial numbers that have already been entered can be displayed in a list in the system settings under master data.

The recorded serial numbers can be tracked here and edited if necessary.

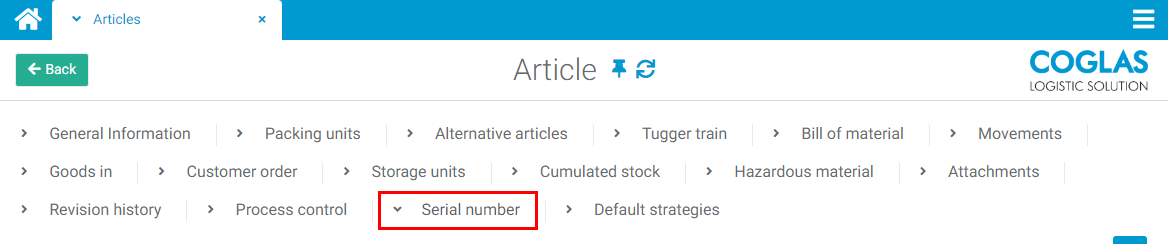

Configuration

To be able to manage serial numbers, they must first be activated for the respective item in the item master data under the "Serial number" tab.

Recording process

Data can be recorded in one of the 4 different processes:

Recording process | Description |

|---|---|

Goods receipt | The recording of serial numbers at goods receipt enables the immediate allocation of incoming items to corresponding orders and storage units. |

Picking customer orders | The serial numbers are recorded and assigned during picking |

Packaging | The serial numbers are assigned to the quants within the packaging. |

Goods receipt without quantum reference | The recording of the serial number at goods receipt is fixed, but without a fixed reference to a storage unit. |

Validation process

Three processes can be selected to validate the serial numbers:

Goods receipt

Picking

Packing

Recording mode

Serial numbers can be recorded in three different modes:

Recording process | Description |

|---|---|

Individually | Each serial number must be recorded individually. |

Start / End | If the serial numbers are sequentially ascending, a start serial number (lowest serial number) and an end serial number (highest serial number) can be entered and all missing serial numbers within the range are automatically enumerated. |

Start / enumeration | If the serial numbers are in ascending order, the number of serial numbers can be specified and the specified number is automatically enumerated based on the start serial number. |

The mode can be selected during recording if several recording modes are assigned to the respective article.

Format specification

If the serial numbers correspond to a certain length, this can be specified with an ‘L’ followed by the length of the serial number. This means that only serial numbers that fulfil this format can be recorded.

Example: L8 = length of the serial number of 8

The regular expressions can be used to specify the format.

Example:

^ABC-\d{8}-99$

For a serial number like this: ABC-12345678-99

Record serial numbers in processes

Goods receipt

The serial numbers supplied can already be entered manually on the order items in the orders.

The number still to be entered is displayed and serial numbers that have already been entered can be deleted.

The entry dialogue closes with the entry of the last serial number. Depending on the entry settings in the process control of the article, the dialogue may look different (e.g. specification of the first serial number or the first and last serial number).

Delivery notes

The serial numbers can also be recorded here if they were not previously supplied or recorded.

In the case of manual collection, this is made possible via the ‘Enter serial number’ button. Alternatively, the entry can also be made for the delivery note item.

Goods in receipt

If there is an item in the goods receipt that has serial numbers activated in process control, the serial numbers must be entered before posting, otherwise the goods receipt cannot be posted in full.

The entry is made as described under Orders.

Customer orders

Serial numbers can also be entered as a default for items with serial numbers in the sales order items.

The serial numbers can either be entered ‘manually’ or conveniently determined using the search function.

Validate serial numbers

Goods in receipt

If the serial numbers have been transmitted manually or via an interface, they can be validated in the goods receipt process to rule out errors when entering them. The validation of the serial numbers in the goods receipt process takes place when the storage units are received. The quantity of the item must correspond to the number of serial numbers recorded. Once all of them have been recorded, the goods receipt can be posted, see also the previous descriptions of orders, delivery notes and goods receipt.

Picking

If the quantity of the items to be picked has been entered during the picking process, the entry of the serial numbers opens with the respective quantity to be picked.

The picking process is only considered complete when the specified number of serial numbers has been correctly validated.

Serial number as a default on the Customer order

If there was a specification for the serial number on the Customer order item, the validation dialogue shows the serial number to be taken; this must now be validated against.

Packaging

When the picked or transported items are packed, the serial numbers must be validated to enable direct allocation.

This is done in the packaging dialogue on the individual items, where the validated serial numbers must match those from the transport and/or picking.

Data interface

Import of serial numbers

Serial numbers can be subsequently imported for storage units and items already in the warehouse.

The import can be carried out either via Excel or JSON format, the current version is SerialNumbers_v1.

Field | Mandatory field | Note |

Mode | Yes | CreateOrModify |

ClientNumber | Yes | Client |

ArticleNumber | Yes | Article number |

Number | Yes | Serial number |

CaptureDate |

| Entry date of the serial number |

CreationDate | Yes | Entry date |

EquipmentBarcode | Yes | Storage unit number |

EquipmentTypeName | Yes | Loading equipment |

GoodsOutDate |

|

|

IsDeactivated | Yes | TRUE oder FALSE |

Please note the following:

The article must be activated under Process control serial number Process control = YES.

The SU number must be available

The article must be on the SU

The same number of serial numbers must be imported as there are article quants on the SU, no more, no less

DeliveryNote/s // GoodsInOrders // PurchaseOrder with serial numbers

Serial numbers can also be transferred for the following message types

DeliveryNote

DeliverNotes

GoodsInOrders

The following also applies here: The customer is responsible for the semantically correct delivery of the serial number data, otherwise the import will be rejected with an error message. This applies to all types of import.

The current version for all message types is xxx_v1.

Transmission of serial numbers for items not requiring serial numbers

If serial numbers are transmitted for items that do not require serial numbers, these are discarded in the processing procedure.

Inventories

Inventory at the warehouse

If a stocktake is carried out on the warehouse stock in the warehouse overview, the serial numbers must be entered, all of them and again, if the stocktake result is different. No selection procedure is offered.

Inventories

Inventories are processed as usual. There is only the following change in the process flow if, after validation of the counting station, a quantity is recorded that is equal to the target quantity.

is equal to the target quantity, there is no serial number validation

is not equal to the target quantity, a serial number validation must take place, as it is not recognisable which serial number may be missing for the SU. This recording process cannot be cancelled!

Warning notice

A wide variety of warning messages can appear in the respective processes. These are always related to the process and are so meaningful that the user can find out the decision correction themselves.

→ back to COGLAS processes

→ back to COGLAS menu